Why Nuclear Power?

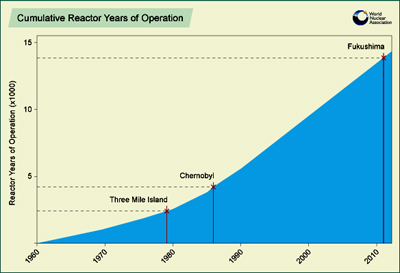

Why, after all the issues from Three Mile Island, Chernobyl, and now Japan, should nuclear power still be considered as a viable source of energy? The answer is that in spite of several negative aspects of nuclear, there are many positives.

1) Most scientists agree that greenhouse gases are building up in the atmosphere and threaten the way of life for humans as well as wildlife in the long run. Electricity generation accounts for about a third of US emissions primarily from burning fossil fuels. Many "green" advocates are now promoting nuclear which has zero emissions (but some other issues). While natural gas has a carbon footprint half that of coal, it is still over 10 times the footprint of nuclear.

2) Solar and wind can not currently replace "baseload plants", the ones that run continuously day and night, providing electricity 24 hours a day. Great advances in electricity storage are needed to allow baseload replacement with solar and wind. Nuclear plants are baseload plants, as are coal and some natural gas plants.

3) While nuclear plants are expensive and take a long time to build (ten years or so). Once they are built, they have a very long life, typically 60 years and maybe longer. Their fuel can be replenished and the facilities upgraded.

4) Nuclear plants are very efficient and have a 90% capacity factor, the percentage of actual output divided by "rated" output. Solar averages about 21% and wind about 36% capacity factors. Nuclear plants are also very reliable, meaning they are rarely down except for scheduled maintenance. Solar is down every night and wind conditions vary widely and are usually low in the summer when electricity demand is at its peak

5) Nuclear plants currently supply about 20% of the electricity in the US, while wind is about 2% and solar is about 0.5%. So realistically nuclear can not be retired by renewables for many years, if ever. Nuclear has remained pretty constant at 20%, while coal is gradually coming down about 4% a year being replaced mainly by natural gas and a small amount of renewables. In 2010 coal generated 45% of our electricity, natural gas 24%, nuclear 20%, hydro 6%, oil 1%, and renewables as a group 4%. Note that for electricity generation in the US, oil is very minor used mainly in Hawaii. Top

Nuclear Fission

Overview: The heart of any nuclear plant is a very large steel vessel which contains the nuclear reactor. Inside the vessel are long sealed 12 foot rods which contain the fuel. The fuel rods, made of Zirconium, are formed into bundles and can withstand extremely high temperatures. Inside the rods are small ceramic pellets, shown on the left, made from uranium dioxide powder. Uranium dioxide is used rather than pure uranium because the dioxide melting point is much higher than that of pure uranium and because it cannot burn as it is already in an oxidized state.

When the reactor is fired up, the tubes heat up to very high temperatures. The heat is removed by a pressurized cooling system using de-mineralized water. The very hot water is then turned into steam which drives a standard electricity generator. The steam is directed through a very large cooling tower (which emits white puffy water vapor plumes as shown above) and is condensed back into water and re-circulated via a closed system.

Nuclear Fission: The "235" in Uranium 235 refers to the total number of protons (92) and neutrons (143) contained in the nucleus of the atom. Natural uranium has only 0.7% Uranium 235 (U-235). U-235 has the property that it decays naturally throwing off small amounts of radiation, i.e. alpha particles consisting of two protons and two neutrons. Most importantly, it can also be "induced" to decay rapidly by bombarding it with a free neutron, which is called "fission". Fission means "splitting".

When a free neutron is absorbed by a U-235 atom, it temporarily becomes a U-236 atom which is unstable. U-236 immediately splits into two smaller atoms and in addition throws off radiation (alpha particles) and three more neutrons. If there are no more U-235 atoms around, the neutrons simply fly off into space.

However, if the free neutrons are surrounded by a dense mass of other U-235 atoms, these new free neutrons then split more atoms and so on, causing a chain reaction. The splitting of one U-235 atom into two smaller atoms releases an enormous amount of energy - about a million electron volts for each split atom. The stored energy in a pound of "enriched" uranium is equivalent to about a million gallons of gasoline.

If the reaction is able to sustain itself, i.e. one of the three free neutrons hits one additional U-235 atom, it is said to be of "critical mass". Then the reaction and temperature of the uranium mass will stabilize. If on average, more than one free neutron hits more than one U-235 atom, the mass of uranium is said to be "supercritical" or "enriched", and the core temperature will rise.

A nuclear plant is maintained only "slightly supercritical" so that the temperature can be controlled. This is done by using control rods. Enriched uranium as used in a nuclear plant has 3% to 4% U-235. An atomic bomb has 90% or more U-235 causing the whole mass to explode within one microsecond. It is worth noting that the fuel in a nuclear reactor can "never" cause an explosion like a nuclear bomb.

Control Rods: The reactor vessel contains a set of control rods that limit the rate of fission inside the fuel rods. Absorbing roaming free neutrons in rods that readily absorb neutrons, means that there are fewer neutrons available to cause fission. Silver-indium-cadmium alloys (80% silver, 15% indium, and 5% cadmium) and boron carbide are common control rod materials. Control rods are inserted into the uranium bundle using a mechanical system that raises or lowers the rods. Raising and lowering the control rods allow operators to control the rate of the nuclear reaction. When an operator wants the uranium core to produce more heat, the control rods are raised (absorbing fewer neutrons). To create less heat, they are lowered into the uranium bundle. The rods can also be lowered completely into the uranium bundle to shut the reactor down to change fuel during maintenance or in the case of an emergency.

As a safety measure control rods are attached to the lifting mechanism by electromagnets rather than a mechanical linkage. In the event of a power failure, the control rods will automatically fall (because of gravity) into the uranium bundle to stop the nuclear reaction. Note that although there are no fission reactions taking place in a shut down reactor, the core bundle continues to "burn" at about 7% of capacity (due to residual heat from secondary decay) which gradually reduces to 1% after a few hours.

The residual heat comes from the natural radioactive decay process of fission materials. Radioactive decay is a natural process by which fission products stabilize themselves by emitting small radioactive particles (mainly alpha particles). Most of the fission by-products decay quickly although a few take a long time. Cooling the shut down reactors was a challenge at Fukushima because of the residual heat after the loss of conventional power. Top

Types Of Nuclear Plants

There are 104 nuclear reactors in the United States. 35 are Boiling Water Reactors (BWRs) and 69 are Pressurized Water Reactors (PWRs). Reactors that use de-mineralized ordinary water are called "light water" reactors. There have been a few "heavy water " reactors, mainly CANDU reactors in Canada, but light water reactors are dominant. The earliest light water reactors were BWRs so we will discuss those first.

Boiling Water Reactors (BWRs)

In the BWR reactor vessel, the fuel rods are kept submerged in de-mineralized water, which acts as a coolant. See the figure at the left, courtesy of the US Nuclear Regulatory Commission (NRC). The water is contained in a pressurized system including the reactor vessel as shown on the left. Because of the pressure, the water has a boiling point of about 550°F. Even with such a high boiling point, the hot fuel rods produce large amounts of steam, which is used to turn the turbine attached to a generator which produces electricity. The steam then flows through a condenser which changes it back to water. A pump circulates the hot water back to the reactor vessel.

Control rods are used to maintain the desired temperature. In a BWR reactor, the control rods are fed from the bottom of the uranium bundle instead of from the top. In case of an emergency in a BWR system, water from a special tank that is under high pressure will automatically (using hydraulics) insert the control rods to quickly shut down the reactor. This is called scramming the reactor.

The condenser has cold water running through it from a water source and it then exits through highly visible cooling towers. The white puffy plumes exiting from the towers are warm water vapor clouds that condense when they hit the much cooler atmosphere (just like breath on a very cool morning).

Pressurized Water Reactors (PWRs)

In a PWR system, water in the "primary loop" is pumped under high pressure through the reactor core where it is heated by fission. The super-heated water then flows to a steam generator where it transfers its high thermal energy to a "secondary system" under less pressure where steam is generated. The steam then flows to a turbine that spins an electric generator.

In contrast to a boiling water reactor, very high pressure in the primary loop prevents the water from boiling within the reactor. A separate vessel, the pressurizer, is connected to the primary loop and is partially filled with water. The water in the pressurizer is heated by submerged electrical heaters which maintain the pressure at about 2,250 psi. The hot primary water, about 600 °F, is pumped into a steam generator, where it flows through thousands of small tubes. Heat is transferred through the walls of these tubes to the lower pressure secondary water system where the water is converted into steam. The transfer of heat is completed without mixing the two water loops, which is desirable because the primary water is radioactive. The steam drives a turbine/generator and is then cooled down into water again by a condenser, the same as in a BWR.

PWRs were originally designed for nuclear submarines, but were adopted by the nuclear power industry and are known as Generation-II (Gen-II) reactors. PWRs are also used in aircraft carriers and in ice-breakers. PWRs are considered superior to BWRs because all the radioactive materials are maintained inside the containment vessel. Top

Containment Systems

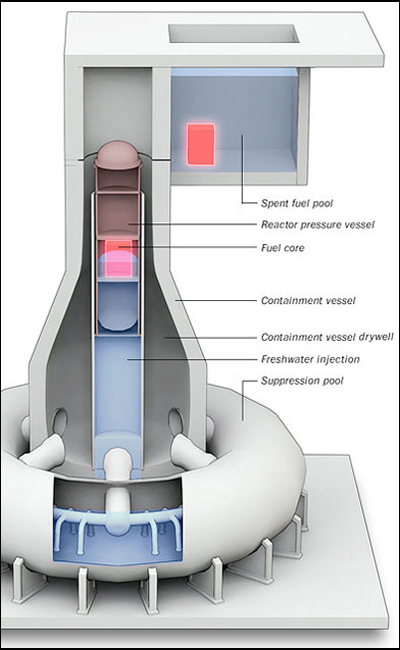

Containment Vessel All nuclear plants have a series of barriers to prevent the escape of radiation in case of some type of nuclear accident. We shall present a brief overview, but not go into the physics of the various elements that can be released in case of a nuclear accident:

1) The first line of defense is the material that makes up the fuel pellet - uranium dioxide. This material can absorb many of the decay radiation elements thrown off by the U-235 fission process which is only about 3 to 4% of the uranium mass.

2) The second line of defense is the Zirconium fuel rod tube material that separates the uranium pellets from the rest of the reactor. The fuel tubes themselves absorb a lot of stray radiation.

3) The fuel core is inside a 12 inch thick steel "pressure vessel", the third barrier, which has been designed to withstand the high pressures of an accident and contain any radiation. See the schematic to the left of a BWR reactor made by GE, and of the type found at Fukushima, Japan (courtesy of the Washington Post).

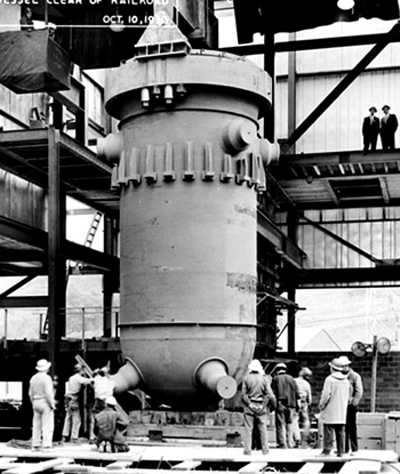

4) The cooling water, the fourth barrier, helps keep the reaction temperature under control and in case of a shut down helps keep the core mass cool. In the case of a BWR, there is a large suppression pool with a significant amount of water inside on the bottom of the reactor. If an accident should happen, huge amounts of steam would be given off and because of pressure it would escape down into the suppression pool with the pipes of steam extending below the water level. The "cold water" in the suppression pool would condense the steam back to water and reduce both pressure and temperature of the pressure vessel. The 1956 picture below is the first US commercial nuclear pressure vessel at Shippingport, PA.

5) The entire primary loop of the reactor – the pressure vessel, pipes, and pumps that contain the coolant water – are located inside the containment vessel. This structure is the fifth barrier to radioactive release. The containment vessel is an air tight structure made of steel and concrete that is 3 to 4 feet thick.. The containment vessel is designed, built and tested for one single purpose: to contain, indefinitely, a complete "core meltdown".

The Zirconium fuel rods begin to break down at 2200°F resulting in a "partial meltdown". A complete "meltdown" occurs when the fuel rod temperatures exceed the 3900°F Zirconium limit and the fuel rod casings completely melt.

Reactor Building Finally, a sixth barrier, the reactor building walls are constructed primarily to prevent anything from entering the reactor from the outside (not particularly to contain radiation from going out). These walls are also made of steel and concrete 3 to 4 feet thick and must be able to withstand hurricanes, tornadoes, earthquakes, plane crashes and terrorist attacks (all events from outside the reactor).

Regulations require that the reactor building must be able to withstand a direct hit by a fully fueled Boeing 767-400 weighing over 200 tons at 350 mph - the maximum speed for precision flying just above the ground. Several mathematical studies have confirmed that the reactors would not be seriously damaged and would not leak radiation.

In 1988 Sandia Laboratory did an experiment with a real rocket propelled F4 Phantom Jet weighing 27 tons at 481 mph colliding with a 12 foot thick slab of concrete that was not anchored. The result was 96% of the aircraft's kinetic energy went into its own destruction with only 4% dissipated in the 2.5 inch thick concrete.

This was done to demonstrate that a proposed Japanese nuclear power plant could withstand the impact of a high speed heavy airplane crashing into it. In 1992, the Turkey Point Nuclear Plant on the southern tip of Florida was directly hit by Hurricane Andrew. No damage was done to the containment building. The plant was built to withstand winds of up to 235 mph, greatly exceeding the maximum winds ever recorded by a category 5 hurricane. Top

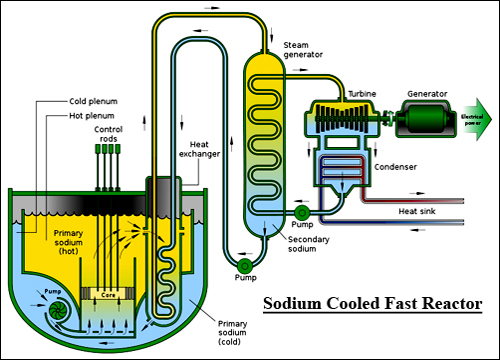

Fast Breeder Reactors (FBRs)

Neutrons produced by fission have high energy and scatter quickly. These fast neutrons do not perpetuate fission as efficiently as slower moving ones so they are normally slowed down by a process called "moderation". A liquid moderator, usually water, cools the neutrons to optimum energies for fission. These slower neutrons are called thermal neutrons because they are brought to the same temperature as the surrounding coolant.

However, a fast reactor uses a coolant that is not an efficient moderator, usually liquid sodium, so its neutrons retain their high energy. Although these fast neutrons are not as good at perpetuating fission, they are readily captured by an isotope of uranium, U-238, which then becomes plutonium (Pu-239).

Plutonium is a better fissioning material than the original U-235. In normal Gen-II reactors the fuel contains about 3 to 4% U-235, but the same fuel contains about 90% U-238. All the U-238 atoms are candidates to become Plutonium atoms and when fission begins in a fast reactor more Plutonium fuel is created than U-235 fuel is consumed - hence the name "breeder" reactors.

According to Nature magazine, "breeder reactors make it possible to obtain 50 times more energy from a given amount of natural uranium than can be obtained with present light water reactors." Replacing all current nuclear reactors with fast breeder type reactors would add about 11,000 years to the current nuclear fuel supply, now estimated to be 230 years.

Fast breeder reactors can also be used to produce enough Plutonium to create nuclear weapons. However to extract the Plutonium, the enriched fuel must be "re-processed" which risks higher radiation exposure and risks the proliferation of more nuclear weapons around the world.

Therefore Presidents Gerald Ford and Jimmie Carter banned "re-processing of commercial spent fuel" in the US. It is also questionable if FBRs are economically worth while as they are much more capital expensive than conventional reactors. There have been a few experimental fast reactors in the US, but they have all been shut down. The U.K., Germany and France have also shut down their FBRs.

Shown to the left above is the Superphénix Reactor in France which was decommissioned in early 1997. Only India, Russia, Japan and China currently have operational Fast Breeder Reactor programs. Most noteworthy is the Prototype Fast Breeder Project in India. A small "test" fast reactor has been operating in India since 1985 in addition to its 17 conventional reactors. India has an abundance of thorium which can be used instead of uranium as a nuclear fuel. India has a three stage nuclear program. The first stage is to build a prototype full size fast breeder reactor in Kalpakkam that will use normal uranium as a fuel. The reactor under construction is shown at the left.

At least two more first phase reactors are planned. The second stage is to operate FBRs that will use Plutonium extracted from spent fuel from the first stage. The third stage will be to utilize the vast Indian thorium reserves as nuclear fuel to give the country energy independence. There is one downside - the liquid sodium which is used to cool the fuel and drive the steam generator is highly flammable if it comes into contact with either air or water. Other fast reactors around the world using liquid sodium as a coolant have had problems with leaks that then burst into flames. The test reactor in India has never had a fire in over 25 years. But since Fukushima, some media have expressed concerns over the long term safety of fast reactors using liquid sodium as a coolant. Top

Spent Fuel Systems

Cold Shut Down To induce a cold shut down, a reactor's control rods are completely inserted into the core mass forcing U-235 fission to come to a halt. However, secondary radiation continues from fission by-products as the core temperature falls to about 7% of normal. It drops to about 1% of the normal temperature after two hours, to 0.5% after one day, and 0.2% after a week. Even then it must still be cooled, but being immersed in water does the job.

When the water temperature decreases below 100°C at atmospheric pressure the reactor is said to be in "cold shut down". Spent nuclear fuel is about 95 percent uranium. One percent is plutonium.

The other heavy elements have extremely long half lives and take hundreds of thousands of years to lose their radioactivity. About 4 percent are other by-products of fission that break down completely in about 300 years. In any case, these elements are active far longer than the 40 to 60 year licenses of a nuclear plant.

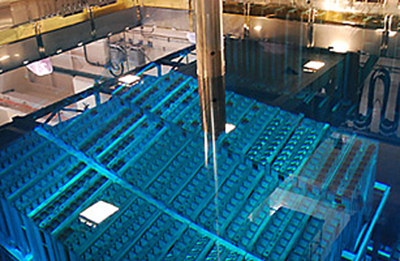

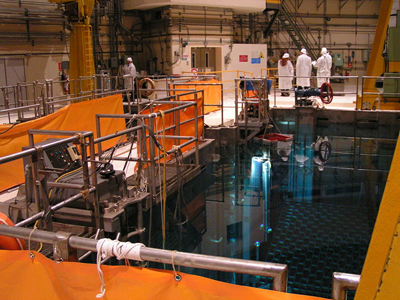

Spent Fuel Pool Storage The average nuclear reactor generates 22 tons of spent fuel each year, times 104 reactors equals about 2,300 tons of spent fuel yearly in the US. Multiple spent fuel rods generate intense heat and dangerous radiation. After a cold shut down, the spent fuel is removed from the containment vessel and placed in an on site water storage pool located close to the original reactor. The picture of the pool to the above left is the actual Fukushima Number 3 storage pool, taken before the earthquake and tsunami.

Storage tanks are made of steel and reinforced with concrete. The spent fuel rods never come out of water. There is a moat between the core reactor and the pool storage unit and a automated mechanical rail system moves the rods under water to protect workers from radiation. The water has a blue cast to it because it contains boron which is a good radiation absorbent.

A typical pool is 40 feet deep and on the bottom of the pool are 14 foot high storage racks to hold the spent fuel rods (fuel rods are 12 feet long). While only 8 feet of water over the 14 foot racks is needed to keep radiation levels in check, the extra 32 feet of depth provides a safety margin and allows fuel rods to be manipulated without special shielding to protect the operators. Current regulations permit re-arranging the spent rods so that maximum storage efficiency can be achieved. The maximum temperature of the spent fuel bundles decreases significantly between 2 and 4 years, and less from 4 to 6 years.

Water quality is tightly controlled to prevent the fuel and its cladding from degrading. The pool water is continuously cooled to remove the heat produced by the spent fuel rods. The water temperature under normal operating conditions is kept below 120°F. The air in the room of the pools, as well as the water, must be monitored and treated as water may be split by residual radiation into hydrogen and oxygen gases, which could cause an explosion (and did at at Fukushima). All storage pools are designed to withstand earthquakes that might occur within a 200 mile radius. Spent fuel rods are kept in pools for a minimum of 5 years.

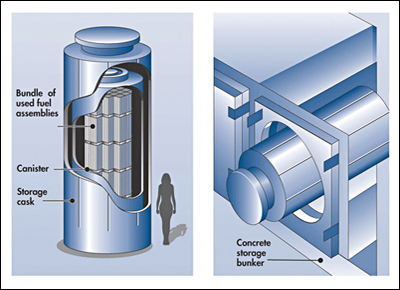

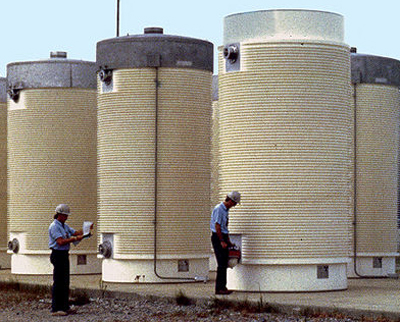

Cask Storage As spent pool capacity is reached, as is the case with many installations today, plant operators may use above ground dry storage casks. Fuel that has been stored for at least five years in water has cooled sufficiently, and its radioactivity decreased enough, for it to be removed from the spent fuel pool and loaded into casks. The exterior of the cask is usually a steel cylinder that is either welded or bolted closed and provides a leak proof containment of the spent fuel. Inside the cask the spent fuel is surrounded by an inert gas inside a second steel container. Concrete is poured between the two cylinders to provide radiation shielding to workers and the public.

There are various dry storage cask designs. With some designs, the steel cylinders containing the fuel are placed vertically in a concrete vault. Other designs orient the cylinders horizontally in the vault.

The concrete vaults provide the radiation shielding. A completely different type of cask design orients the steel cylinders vertically on a concrete pad at an open cask storage site (example shown at the left).

The Nuclear Regulatory Commission (NRC) must approve the designs for spent fuel dry storage systems. In addition, the NRC periodically inspects the fabrication and the use of dry casks to ensure operators are performing in accordance with radiation safety and security requirements.

Dry spent fuel storage in open casks is considered to be safe and environmentally sound. Over the last 20 years, there has been no radiation contamination and no known attempts to sabotage spent fuel casks. Cask storage is estimated to be good for 100 years. Top

What Are The Nuclear Risks?

Good Safety Record

There is no question that the commercial nuclear power industry in general has had a very good safety record. The graph to the left shows that there have only been 3 accidents out of over 14,000 reactor years of operation in 32 countries. Outside of Chernobyl, there have been zero deaths from commercial nuclear power plants. The industry can be characterized as one where the probability of an accident affecting the public is very, very low, but when one does happen, the consequences can be serious.

However, It should be emphasized that a commercial type nuclear power reactor cannot under any circumstance explode like a nuclear bomb.

Further, testing has shown that less radioactivity escapes from molten fuel than was initially assumed. Radioactive material can not easily venture beyond the immediate internal barriers of the containment vessel. Thus, even if the containment structure that surrounds all modern nuclear plants were ruptured, it would still be highly effective in preventing a wide ranging escape of radiation.

Spent Fuel Pools

Three quarters of the US spent nuclear fuel sits in water cooling pools outside of the thick concrete and steel barriers that guard the guts of a nuclear reactor. Some experts say some of the pools in the United States contain four times the amount of spent fuel that they were designed to handle. Safety proponents have long urged the NRC to force utility operators to reduce the amount of spent fuel in their pools. The more tightly packed they are, the quicker they can overheat and spew radiation into the environment in case of an accident, a natural disaster or a terrorist attack. Most of the radiation release from Fukushima came from the hot spent fuel pools (See the Fukushima Accident section below).

Long Term Storage

Storage casks in the US are normally kept outdoors, generally on concrete pads and industry officials insist they are safe. Unlike the pools, the casks don't need electricity; they are cooled by air circulation. They are kept in secured areas usually behind high walls topped with barbed wire. If a terrorist attacked a fuel cask and managed to put a hole in it, the consequences would be very local and would be contained within the plant site. Nuclear plants do maintain tight security around the clock. But the 100 years that a cask will last is not long enough, a better system is needed. One that will last thousands of years.

A 1982 law designated the federal government as responsible for the long term storage of nuclear waste. The plan was to start accepting waste in 1998. After 20 years of study, Congress passed a law in 2002 to build a nuclear waste repository deep in Yucca Mountain, Nevada. The federal government spent $9 billion planning the project, but the next administration cut its funding and recalled the license application to build it. Nevadans have fiercely opposed Yucca Mountain. But even if a facility had been built, America already has more commercial nuclear waste (72,000 tons) than Yucca Mountain could have contained. President Barack Obama wanted to expand nuclear power. He created a commission to come up with a long term nuclear waste plan.

A report from MIT, The Future of Nuclear Power, updated in April 2011, strongly recommends "that an interim solution be developed to remove spent fuel from storage facilities at reactor sites, and move it to regional, medium-term repositories where the fuel can be monitored and protected as it decays over time. Spent fuel loses much of its radioactivity with every passing decade, as the most dangerous radioactive isotopes decay and lose much of their potency during the first 50 years. This diminishes the problem of long term storage." Top

Fukushima Accident

The Fukushima nuclear accident on March 11, 2011 focused the industry on cooling systems. Loss of grid power, for whatever reason, forces a nuclear power plant to depend on internal back up systems. After the Japanese earthquake automatically shut down the core reactors at Fukushima, the back up generators worked fine and kept cooling the spent fuel in the pools. Then an hour or so later, the huge tsunami took out the back up generators. The back up batteries then kicked in and continued to operate the cooling systems. But after eight hours the batteries were exhausted and the cooling systems finally shut down.

At this point the residual spent fuel heat could not be carried away any more. As the water heated up, it began to boil and release steam which increased the pressures inside the buildings. Operators followed standard procedures and released small amounts of radioactive steam periodically through filters and scrubbers. The very small amounts of radiation caused no harm to workers or the public. However, as the cooling water boiled off, eventually the fuel rods were exposed and temperatures exceeded 2200°F - the point where their Zirconium cladding begin to break down. This triggered a reaction between the Zirconium and the water which produces hydrogen gas. Hydrogen gas is extremely combustible and when enough of it mixed with the oxygen in the air above the pools, several major explosions occurred and a lot of radiation was released into the atmosphere.

This incident reminded the world of how crucial it is to cool spent nuclear fuel pools. The Fukushima accident has caused the NRC to schedule a review of US reactors and how to deal with total power loss. One of the major issues with US cooling pools is that back up power is not mandatory. This issue should be at the top of the NRC list.

Fukushima Core Meltdown

Shown at the left is reactor No.1 at the Fukushima Plant after the explosion that blew its roof off on March 12, 2011. At first it was assumed that the explosion was due to the cooling pools overheating, boiling off some of the water, zirconium fuel rod cladding breaking down and forming hydrogen gas, which then mixed with the oxygen in the air above the pool and exploded. This did happen for sure at unit No. 4 which had been shut down for over 3 months and whose fuel core was in the cooling pool. However, during April, 2011 cesium-137 and iodine-134 were discovered 25 miles from the Fukushima Plant in fairly high concentrations leading some foreign scientists to believe that a fission reaction had taken place from a possible core meltdown in one or more reactors.

On May 12th Tokyo Electric Power Co. (TEPCO) announced that nuclear fuel in three of the plant’s reactors (units No. 1, 2, and 3) had indeed melted. Engineers from TEPCO had entered the No.1 reactor for the first time on May 5th and saw that the cooling water level in the pressure vessel was three feet below the fuel rods which had been totally exposed to the air and had fully melted down. On May 26th, Naoto Sekimura, a Japanese nuclear engineer at the University of Tokyo, announced that "Nuclear fuel at the Fukushima Daiichi power plant began melting five hours after Japan’s March 11th earthquake. About 11 hours later, all of the uranium fuel in the facility’s No. 1 reactor had slumped to the bottom of its inner containment vessel, boring a hole through a thick steel lining." Experts concluded that the explosion in unit No.1 was most likely due to hydrogen build up in the pressure vessel after the meltdown. Also radioactive water leaked into the ocean from cracks in the containment vessels and possibly from leaking pipes. Vast amounts of contaminated water from fire trucks and cement pumps accumulated in the basements of the reactor buildings and in other low areas. Measures were taken to plug the known leaks and to adequately store and treat the exposed water.

Shown at the left is a photo of the construction of a complete overall cover for reactor #1 (same reactor as in the photo above) taken in the fall of 2011. The individual covers are made of heavy duty 20 square meter rectangular polyester sheets fastened to a steel frame. The individual sheets are stretched fast by weights totaling 19 tons. The panels were placed by two huge cranes each capable of lifting 750 tons and are now very contaminated from local radiation. The covers prevent the escape of radiation from the damaged reactors into the atmosphere. Covers have been completely installed on reactors #1, #3, and #4 and all units have been declared to be in cold shut down (reactor vessel temperatures under 100°C) as of December, 2011.

As a result of the accident at Fukushima, nuclear teams all over the world are reviewing their emergency plans for such a disaster, including losing grid power, loss of cooling water, etc. In the aftermath of Fukushima, both Germany and Switzerland have decided to phase out nuclear power in the long run. Germany will do so by 2022 and Switzerland by 2034. This is expected to have a significant boost for renewable energy sources, especially solar and wind. For a very detailed account of the earthquake/tsunami on the Fukushima Plant and Japan see Fukushima Disaster. Top

Re-processing Nuclear Fuel

As mentioned above under Fast Breeders, "commercial" spent fuel re-processing in the US is not an option at this time, although several organizations continue to push for it. Advocates claim that because of extreme environmental and political backlash, America's "once through and bury" policy is not workable and the long term storage issue is simply in limbo.

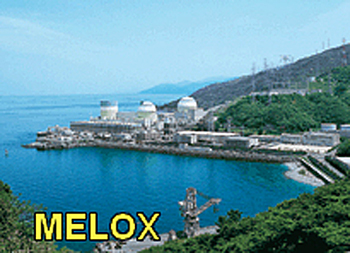

France is by far the leading re-processor country and their premier facility, La Hague, is shown at the left. A re-processing plant built in the US similar to La Hague and its sister site Melox is estimated to cost between $20 and $25 Billion. (For reference, a typical nuclear reactor site costs about $10 Billion.) No privately owned power utility could afford that kind of financial commitment. A re-processing plant would have to be financed, if not owned, by the US Government. With Congress divided on just about every subject, the chances for a US re-processing plant are indeed remote.

An aerial view of La Hauge is shown at the left. Newly spent nuclear fuel rod bundles, which are highly radioactive packages of long metal rods, are gripped by large robotic arms. They are then hoisted by cranes and placed on belts that move them into four very large cooling pools. They will sit in these typical cooling pools for three years to cool and protect the workers.

Then robotic machines will lift them out, chop them up and put the pieces to be processed into vats of nitric acid. Through a "chemical process" (no nuclear reactions) called PUREX (Plutonium URanium EXtraction), the elements that still contain energy, uranium and plutonium, are separated from the other fission products. Further chemical processing separates the plutonium (1%) from the uranium (95%).

Spent fuel rods also contain other elements (4%) that have relatively little energy, but plenty of long lasting radiation. These radioactive elements are collected and immobilized by sealing them in tough, durable glass “logs”. The log glass is a very robust material that resembles volcanic glass and it will keep the radioactive materials safely sealed from the environment for hundreds of thousands of years.

About 96% of the energy in normal spent nuclear fuel remains available for reprocessing while only 4% is "true waste". The re-captured plutonium from La Hague is sent to the Melox facility in southeastern France where it is used to make MOX fuel. MOX, Mixed OXide fuel, is nuclear fuel that contains two fissile materials, plutonium and uranium.

MOX fuel is an alternative to the low enriched uranium (LEU) fuel normally used in light water reactors. A mixture of 6% plutonium and 94% uranium reacts similarly, but not identically, to LEU fuel. The re-captured uranium could also be used in the MOX fuel, but is not currently because it is cheaper to use "fresh" uranium. It is believed that as the price of uranium rises in the future, the re-captured uranium will be re-used.

About 30 thermal reactors in Europe are using MOX fuel and 20 more have been licensed. The largest nuclear complex in the US, the APS Palo Verde plant 50 miles west of Phoenix, Arizona (shown below) was designed for 100% MOX capability, but has always operated using LEU fuel.

Areva, the huge French Utility which owns La Hague and Melox, says re-processing reduces the volume of the highly radioactive nuclear spent fuel by 75% by removing uranium and plutonium from the storage operation. The remaining "true wastes" in the glass logs will be stored until France constructs a deep geological repository planned for 2025. The re-processed plutonium has a significantly shorter radioactive lifetime by a factor of about a 1,000 because it does not contain long lived isotopes. However, the spent MOX fuel is initially "hotter" than "once through" fuel, but then cools rapidly.

The Areva solution is not a nuclear panacea. It does reduce the initial nuclear spent fuel by 75%, but the glass rods have to be stored and buried, and the "second time through" Mox fuel has to be stored and buried. There is considerable debate as to whether or not the total volume of waste product over a given amount of time is less with re-processing. Areva says there are big waste volume savings (75%), but nuclear critics say there is none.

Considering the total life cycle of "twice through" fuel, there does not appear to be any significant cost savings and several studies confirm this. However, re-processing significantly reduces the life span of the spent radioactive materials, simplifies the management of eventual repository-bound spent nuclear fuel, and removes dangerous plutonium from military sources.

Japan, Germany, Switzerland, the Netherlands, Belgium and Italy are currently shipping their spent fuels to France for re-processing. Eventually, after their glass logs cool down, the logs will be shipped back for disposal in their respective countries at 25% of the original volume. The re-processed plutonium will be used in MOX fuel.

The US Government has contracted The Shaw Group construction company and technical partner Areva, now called Shaw Areva MOX Services, to build a new plant at the original "military" re-processing Savannah River Site close to Aiken, South Carolina to re-process military spent nuclear fuel. (For an interesting history of US military fuel re-processing click here.) Plant construction of the "MOX Fuel Fabrication Facility" was started in August, 2007 and is scheduled to be completed in 2016. See the construction picture above. The Facility will process 3.5 tons of weapons grade plutonium per year. The Tennessee Valley Authority is interested in using the MOX fuel that will be converted from weapons grade plutonium. This has never been done before and a few technical issues have surfaced. (For an interesting history of this project click here.) However, at this time there are still no plans for re-processing "commercial" nuclear waste per US Government guidelines. The Obama administration committed only to more re-processing research with anti-proliferation goals in mind.

Top